Our organic shirataki noodles are made using refined konjac powder. Produced using the traditional methods, this variety can readily absorb the colors as well as the flavors of whatever ingredients they are prepared with, making them doubly appealing to the eyes as well as the taste buds. A good choice for those beginning to introduce shirataki into their diet. Available loose or knotted.

-

Packaging options

Available in 200g bag

-

Making

Mitoku’s organic soba and udon producer has been in business since 1877. They remain a family-run business committed to delivering noodles that are honest, high in quality, and grounded in tradition. Each batch reflects generations of knowledge passed down.

Their factory is located in Nakai, Kanagawa Prefecture, where natural surroundings, clean water, and ideal climate conditions support our production. They incorporate the strengths of Japanese agricultural practices, food science, and engineering to deliver products trusted by customers at home and abroad.Situated in Nakai, Kanagawa Prefecture, an area blessed with natural surroundings, clean water, and ideal climate conditions, our supplier utilizes these natural resources while drawing on labor-intensive techniques passed down through the generations to produce noodles of the utmost quality.

The noodle-making process begins with the selection and blending of high-quality flour, which should be aromatic with gentle elasticity.

Next comes the addition of fresh water from the local river. The water is slowly and firmly kneaded into the dough. For salted noodles, mineral-rich sea salt is added.When making udon, it important to get a good, thick, chewy texture. To achieve this, the dough must be firmly kneaded then allowed to rest to develop the wheat gluten. Traditionally in Japan, this was done by treading on the center of the dough to release air from the mixture, giving it a stronger texture. Nowadays, the same result is achieved by pressing the dough mechanically. Because soba contains either small amounts of wheat or no wheat at all, this additional process is not required. In addition, if soba noodles are dried for too long, they will become brittle and dis-colored. For this reason, soba is produced over a shorter time period than udon.

After the dough has been formed, it is passed through a series of rollers to form long, continuous sheets with a more or less even consistency. The sheets are then allowed to rest without being pressed, which deepens the umami flavor. Once this step is completed, the sheets are cut into long, thin strings called mensen, which are matured for a further five hours until they begin to dry.

One of the most important elements in producing umami-rich, delicately textured noodles is the final drying process. The mensen are taken to a special drying room, where they are suspended from rods and allowed to dry gently and gradually over the course of about twenty-four hours. This slow drying process provides the noodle with superior depth of flavor. Lastly, the dry strings are cut into different sizes and packaged, and, once the final checks have been carried out, the product is ready.

-

How to use

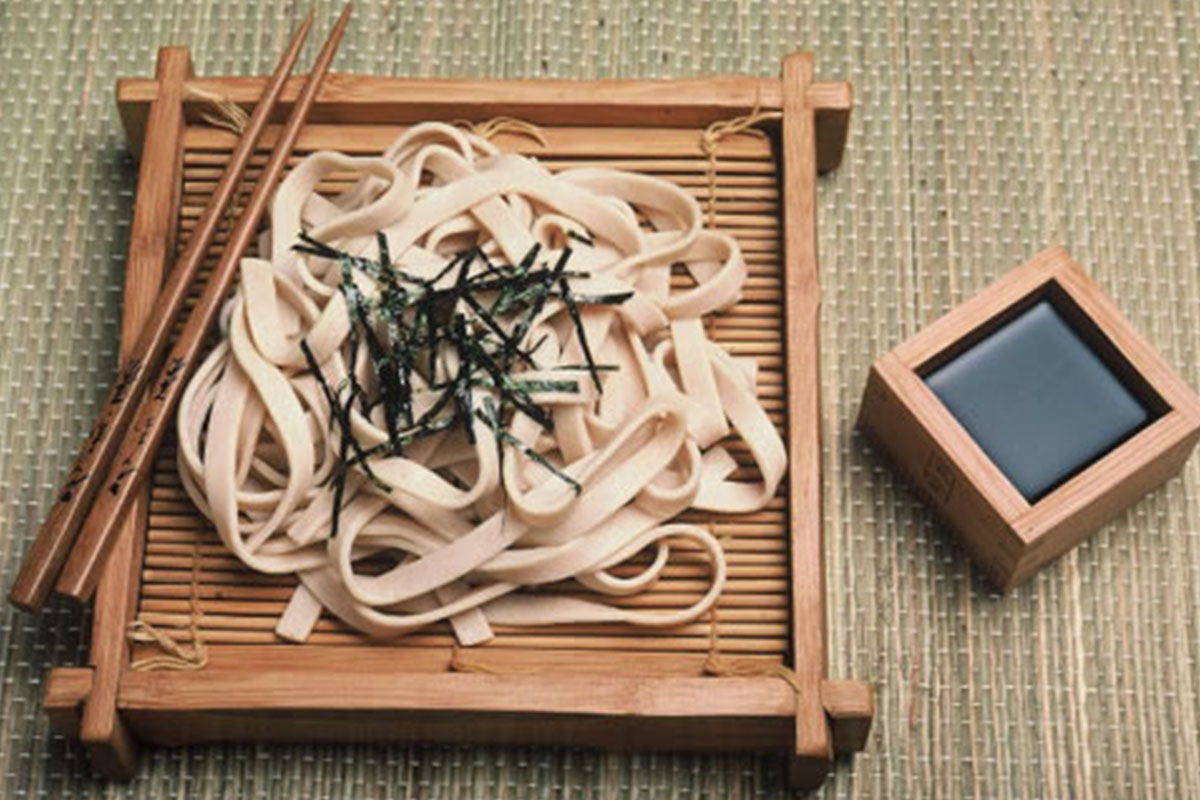

During the heat of summer, noodles are deliciously refreshing when served floating in a bowl of ice water and accompanied by a chilled dipping sauce. For warmth in the winter, noodles are commonly served in piping hot broth. Whether in soups or salads, sautéed with vegetables, deep-fried, baked, or topped with sauce, noodles are delicious.

Quick to prepare, they provide the perfect solution when you have unexpected guests. In the time it takes for the water to boil and the noodles to cook, you can prepare a broth or sauce and a vegetable dish and voila! In twenty minutes you can create a nutritious and satisfying meal.

Since most Japanese noodles are made with salt, it is not necessary or advisable to add salt to the cooking water. In a large pot, bring the water (about ten cups of water for every eight ounces of noodles) to a full rolling boil. Add the noodles a few at a time so as not to completely stop the boiling. Stir gently until the water is boiling rapidly again to prevent the noodles from sticking to the bottom of the pan. If too many noodles are added at once, the water will not quickly return to a boil and the noodles will be overcooked on the outside and undercooked on the inside. Also, using too little water will result in sticky, unevenly cooked noodles.

There are two acceptable methods for cooking noodles. The first method is quite basic. Simply bring the water in the pot back to a rapid boil once all the noodles have been added (as just described), then cook the noodles over medium heat until done. The second method is known as the “shock method”. Once the noodles have been added to the pot and the water returns to a rolling boil, a cup of cold water is added to “shock” the noodles. When the water returns to a boil again, another cup of cold water is added. This is repeated three or four times until the noodles are cooked. No matter which method is used, noodles should be tested often to avoid overcooking. A properly cooked noodle should be slightly chewy. When broken in half, the noodle should be the same color throughout.

Once cooked, immediately drain and rinse the noodles in two or three cold-water baths or under cold running water to prevent further cooking and to keep the noodles from sticking together. When they have cooled enough to handle, drain and set aside until ready to assemble your dish. If reheating is necessary, place individual noodles in a strainer or colander and submerge in a pot of boiling water until just heated. Drain well and serve.

The noodle cooking water can be reserved, allowed to sour slightly, and then used as a natural leavening agent in breads, muffins, and pancakes.